Feature

01 Compact, Lightweight, and Highly Accurate

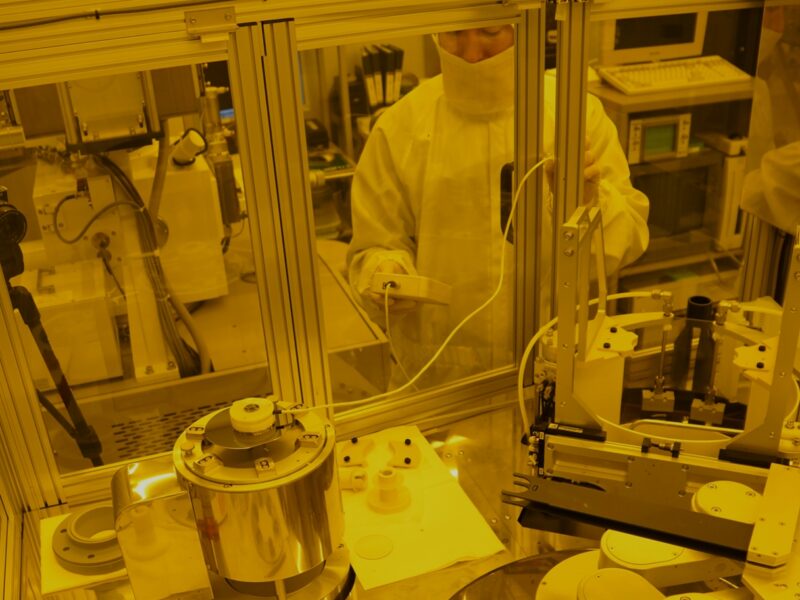

Unlike other heavy precision levels, our precision digital level is compact and lightweight, making it easy to measure on wafers and robot arms, where heavy objects cannot be placed. This makes it possible to reduce manpower and man-hours required for measurement and adjustment of large equipment. The angular accuracy of the level X and Y axes is ±0.001deg (17.5μm/m), which is extremely high precision, and these features are widely used in the assembly and installation of semiconductor manufacturing equipment and other precision machinery that requires precise adjustment.

02 Intuitive adjustment is possible with graphic monitor displaying bubble position

Because our precision digital level is literally “digital,” it can display measurement results as numerical values in the Cartesian coordinate X and Y axes. While the numerical display has the advantage of data management, it is difficult to visualize the state of the level and to make adjustments in the field. Our digital level reproduces the level in a graphic representation of the 2-axis plane of the monitor, allowing precise adjustment as if you were looking directly at the bubble of the level. This makes it easy for even first-time users to introduce the system, and it has been adopted at many job sites.

03

Reduction of operator variation,

Improved workability

In addition to the ability to graphically display measurement results in a biaxial plane, our precision digital level has an additional function to set the acceptable angle range. This function alerts the operator when the horizontal angle is within the acceptable range with a “Good” indication on the monitor and an audible tone. The passing range can be determined by the user’s own criteria. This function reduces variation in leveling work among different operators. Furthermore, even novice operators can learn leveling easily and in a short time.

04 Capable of taking measurements at a distance

A typical bubble level requires the human eye to directly check the state indicated by the level, making it impossible to measure in narrow or high locations where the level cannot be seen by the human eye. In contrast, our precision digital level has a separate sensor and monitor, which allows the sensor to be placed at a distance from the level, making measurement possible. We have a lineup of both wired and wireless types, which can be selected according to the operating environment and application.

05 Full Lineup and Extensive Delivery Record

We have listened to diverse market needs and have continued to develop technologies and products to solve our customers’ problems, including the development and design of standard products such as 2-axis precision digital levels and separate inclinometers, as well as many custom products. These precision digital levels and inclinometers are now used in many industries, ranging from the assembly and adjustment of semiconductor manufacturing equipment to the adjustment of equipment for advanced safety vehicles (ASV) and machine tool equipment, as well as the leveling of robots at the reference arm position to horizontal adjustment in the construction, civil engineering, and surveying industries. Our products are used in many industries, contributing to manpower saving and workability improvement in the precision horizontal angle measurement and adjustment of equipment and devices.