Blogs

2025.04.04

Is the measurement environment ready for a digital level?

How did you choose the house you live in? You may have considered the sunlight, the layout, the number and size of rooms, and if it is an apartment or condominium, the number of floors to choose from.

You would also be setting up your living environment by adding furniture and appliances to your room to make your life more comfortable.

In fact, our digital level also provides stable measurements and reliable data by selecting the room’s exposure to sunlight and the number of floors, and by preparing the measurement environment.

Now let’s talk about what kind of room is good for a digital level!

・Rooms should be located facing north (north side) with little sunlight.

If you were to consider actually living in the house, many of you would probably choose a sunny and bright south-facing room. However, if you think about using a digital level, you would choose the opposite: a room with less sunlight.

In fact, the way the sun shines on the pillars supporting the room causes the steel rods inside the pillars (reinforcing bars) to stretch in different ways, resulting in a subtle tilting of the room.

This “minute tilt” cannot be detected by the human eye, but it can be detected by our digital level (for example, it is like knowing that an object placed 100m away has moved up 2mm), which affects the leveling measurement.

It can be said that a north-facing room will receive less sunlight than other orientations and thus have less impact on measurements.

・The room should be on the first floor.

For security purposes, the higher the floor, the better, but for the digital level, the lower the floor, the better.

As I mentioned earlier about the difference in the way columns extend, the same can be said about the number of storeys. The higher the number of storeys, the longer the columns and the more likely they are to lean.

・Prepare a horizontal reference.

Before measuring anything with a digital level, it is necessary to check that the reference of the digital level’s sensor is not out of alignment. Then, what kind of thing should be prepared as a reference?

For example, a stone surface plate would be one of them. Stone surface plates conform to the Japanese Industrial Standard JISB7513-1992 “Precision Surface Plate,” of which the smaller the grade number, the flatter and better the surface plate. However, even though the surface plate itself is flat, if it is placed on an inclined surface, it is creating a slope of the stone.so it is necessary to adjust the level including the location of the surface plate.

(on an adjustable platform)

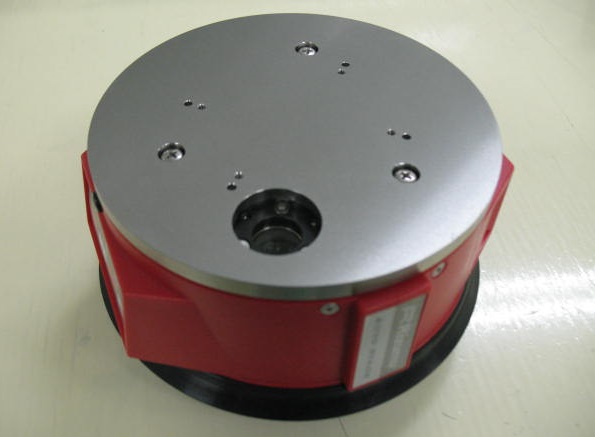

ASW-21S (Optional specification)

The Auto Stage ASW-21S (optional specification), a product in our product lineup, can also play a similar role as a stone surface plate.

The silver stage of the ASW-21S automatically levels itself even if the installation surface is tilted. On that stage, you can check to see if the sensor reference of the digital level is off.

There is another advantage over a stone surface plate: it is lighter than a stone surface plate. Stone surface plates are heavy and difficult to carry around, but the ASW-21S is lighter than stone surface plates, so it can be used for leveling without having to choose a location.

We’ve talked about choosing a room for a digital level and setting up a measurement environment.

If you are worried about the environment for measurement, maybe you can solve that problem, so please give it a try.