Level for roll horizontal adjustment (Roll axis adjustment level)

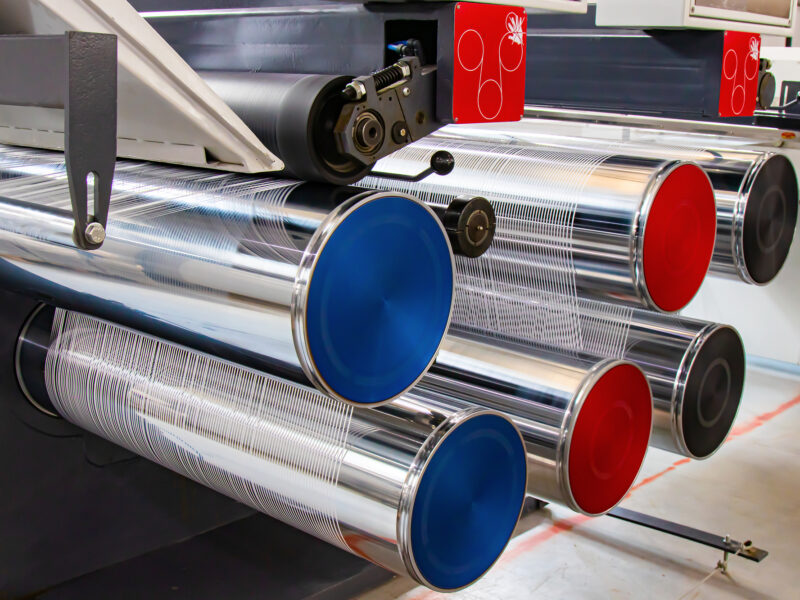

Rolls are often used as parallel rolls in manufacturing lines for paper, vinyl sheets, steel strips, etc. However, if the horizontal accuracy of the roll axis is poor, problems such as transport jams can occur. In other words, paper, vinyl sheets, and steel strips flow to the left or right, and rolled products are not wound up cleanly, resulting in a loss of product quality. In some cases, the product must be discarded. To prevent this, this product is designed to be placed on a flat roll for leveling.

Features

01 Used for leveling horizontal rolls

02 Applicable to rolls with diameters from φ40 to φ200

03 Special jig (*) enables stable measurement of horizontal roll angle

※ See supplementary explanation.

04 Angle measurement range: 2 axis type: ±0.3 degrees Accuracy(repeatability)

2 axis;±0.001 degree(range ±0.3deg)

Supplementary explanation

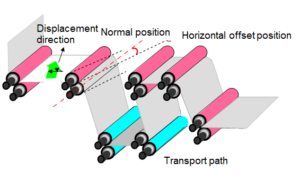

The following is a description of “roll axis misalignment” in conveyor rollers of printing equipment.

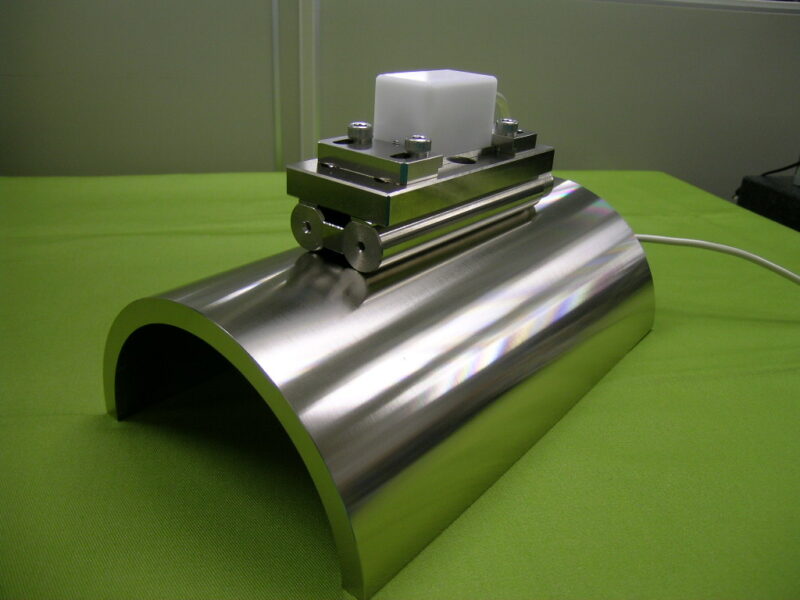

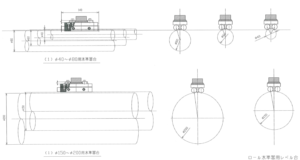

Stable measurement of the roll axis as indicated in Feature0 3 and installation of a digital level are shown below.

The roll axis adjustment level consists of the sensor used in the digital level held in the center of a dedicated jig. Two SUS cylinders are placed on the bottom of the dedicated jig, and when placed on the top surface of the roll to be measured as shown in the figure above, the roll axis and the tangential cylindrical axis of the digital level jig are aligned parallel, enabling stable horizontal angle measurement of the roll axis.

Spec

●Spec

| Sensor part | Linear angle output | X direction ±0.3° (deg) Y direction ±0.3° (deg) |

| Measurement resolution | 0.0002° (deg) max. | |

| Zero point repeatability | Less than ±0.001° (deg) | |

| Response speed | 50ms max. | |

| Operating temperature | -10°C to +50°C | |

| Main unit | Microcomputer | 8bit microcontroller |

| A/D Section | 14bit | |

| Measurement range | ±0.3° (deg) | |

| A/D resolution | 0.000025° (deg) | |

| Display range | 0.0001° (deg) | |

| Pass Range Setting Range | 0.0001° (deg) | |

| Range switching | 0.01 / 0.001 / 0.0001 | |

| OVER display | 0.3deg or more | |

| Function | Measuring time range | 0 to 99 minutes (unit: seconds) |

| Number of sensor connections | 1CH | |

| Display section | Graphic LCD 160✕160 dots with LED backlight |

|

| Power source | Dedicated AC adapter DC 6V 2A 4 x 1.5V AA batteries (or rechargeable AA NiMH batteries) |

|

| Dimensions | Monitor | H180✕W100✕D45 (mm) |

| Sensor section | Φ 50 X 23.5 mm (100 g) | |

| Cable | Standard 2m |