Horizontal Adjustment System (Adjuster automatic adjustment system)

In recent years, the number of skilled engineers and workers on production lines and in field service has been decreasing, and there is a demand for the development of an automatic leveling system to replace the manual leveling work of skilled workers in the precision horizontal adjustment of precision equipment.

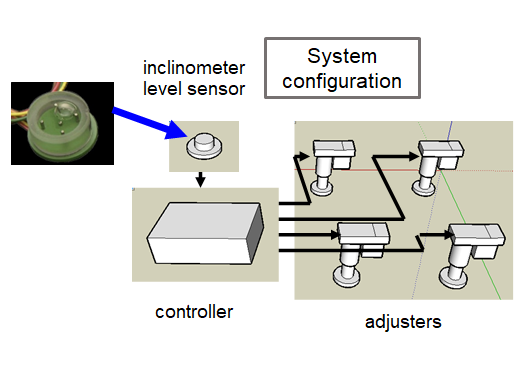

While a level is a measuring instrument that measures angles, an automatic leveling system uses angle data from a level sensor to adjust the table height using multiple drive shafts (such as an auto-adjuster unit), and is an application of our product, the leveler.

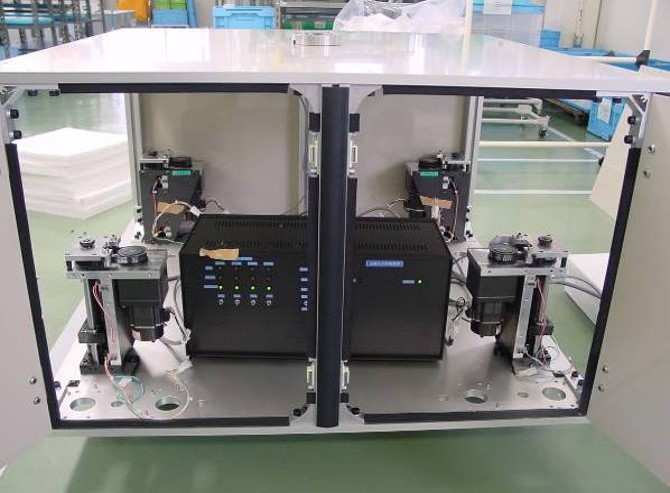

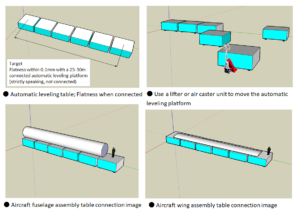

The Autostage uses one fixed shaft and two movable shafts to adjust the table height, but a removable multi-axis motorized adjuster is required to automatically level equipment of various manufacturers. The system is automatically controlled by feeding back the signals of the 2-axis level sensor (Z-18).

Features

01 The system maintains the table level by applying the level sensor of a digital spirit level and driving a level-control actuator.

02 Significant reduction of leveling man-hours by shifting from manual leveling to an automatic leveling system that can be easily performed by anyone

03 Automatic leveling with 4 or more vertical multiple axes

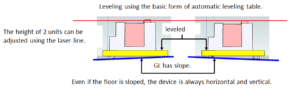

04 Automatic horizontal adjustment even when four or more vertical multiple axes are arranged in a polygonal shape

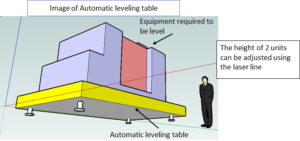

05 Vertical movement of the horizontal plane while maintaining the level due to the connection of automatic leveling tables

06 High degree of freedom in rearrangement of automatic leveling tables and readjustment of the horizontal level due to layout changes, etc., enabling a significant reduction in man-hours.

Supplementary explanation

Example of prediction: Multi-connected pedestal for installing ultra-large precision structures

⇒ cradle for mounting passenger aircraft wings,

cradle for manufacturing propellers for ultra-large wind power generation, etc.

Spec

| Sensor | Linear Angle | Xdirection ±0.3deg / Ydirection ±0.3deg |

| Measurement resolution | 0.0002 degrees | |

| Zero Repeatability | ±0.001deg or less | |

| Reaction speed | 50ms or less | |

| Operating temperature | -10℃~+50℃ | |

| Main unit | Microcomputer | 32bit microcontroller |

| A/D section | 14 bit | |

| Measurement range | ±0.3 degrees | |

| A/D resolution | 0.000025 degrees | |

| Display range | 0.0001 degrees | |

| Pass Range Setting Range | 0.0001 degrees | |

| Range switching | 0.01 / 0.001 / 0.0001 | |

| over display | 0.3deg or more | |

| Functions | Measurement time range | 0 to 99 minutes (units are seconds) |

| Number of sensor connections | 1ch | |

| Display section | 4.3 inch color LCD touch panel/480 x 272 dots | |

| Power source | Measurement time range | "Dedicated AC adapter DC6V" 4 AA batteries (1.5V) (AA nickel metal hydride rechargeable batteries are also acceptable) |

| Dimensions | Monitor part | 280g / height 145mm x width 96mm x visibility 35mm |

| Sensor part | Φ50×19mm / 70g (SUS base) | |

| cable | Dedicated cable white 2m |